About Company

G-Centri-Force believes that innovation and quality assurance is key to developing leading machine. We are continuous improve our processes to being our customers innovative quality products and services against centrifuge equipments. To cater to the requirements of Decanter Centrifuge in two phase as well as three phase application, we G-Centri-Force, we established in thereafter year 2008 & we are one of the leading manufacturers and service providers of a wide range of product that are durable and efficient. With rich 8 years in all products experience, set up the company with the aim to provide a complete range of machines and related services been supported by a group of professionals, who understands the requirements of our clients and delivers the products within the stipulated time frame. Some of the exceptional attributes of our company are transparent trade practice, excellent design, low operating cost, effect services, etc. Owing to the maintenance of quality in clients.

WHY G-CENTRI-FORCE

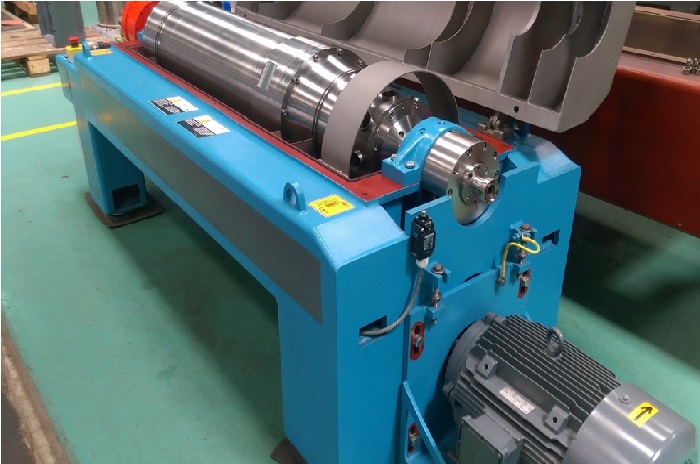

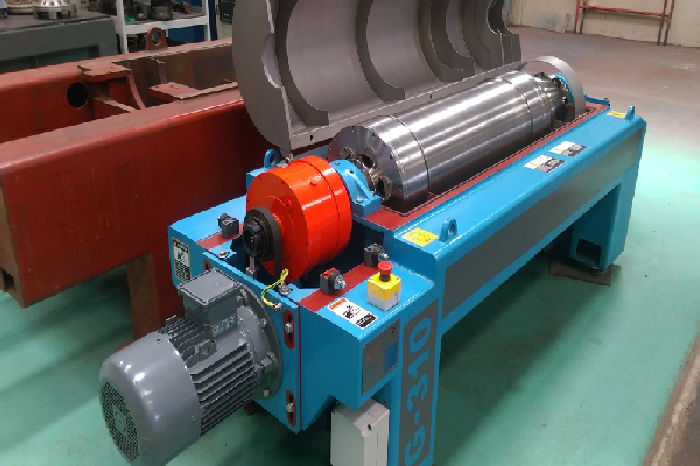

Our capabilities and our knowledge for your success: Decanter centrifuges, in comparison with other types of centrifuge, offer industry by far the greatest application options. At the same time, the decanter is among the most complicated machines in solid / liquid separation. Only a deep understanding of the mechanisms and comprehensive knowledge of processes can ensure the best separation results. With every success story among our customers, our experience grows. We've collected them, along with knowledge and production capacity, for more than a decade and bundled them into our machines and systems. The result is unmistakable concepts developed for the success of our customers.

The typical G-Centri-Force customer is looking for the best solution for their separation tasks. They think in terms of the future, and demand quality and performance. After all, an industrial centrifuge is often in active use for more than 30 years.

G-Centri-Force Offers complete decanter centrifuge Manufacturing servicing and repairs including complete strip, measure, parts and workshop service which is available for all makes of industries centrifuge including waste water, oil & Gas Industries, Fish & rendering, Beverage & Distilleries, chemicals, Sugar, Pulp & Paper, Our service facilities is including 2&3 phase decanters & high speed vertical disc centrifuge.